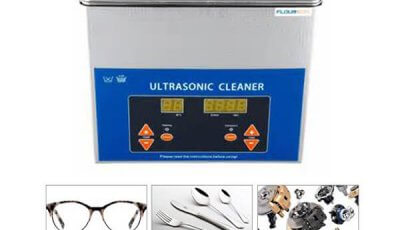

As technology evolves, newer methods are invented and devices become more sophisticated. The ultrasonic cleaner is one such fine example. There are various methods of cleaning different stuff. However, the precision and accuracy that you get with ultrasonic cleaners are remarkable. This is one of the reasons that the ultrasonic cleaning process is widely used across different industries and stratospheres for the maintenance of equipment. The ultrasonic cleaners are used to clean almost everything these days including rifles, jewelry, engine components, surgical parts, motherboards and even the delicate lenses. The range of items which are cleaned using the ultrasonic cleaning process is huge and that implies the efficiency of the process.

As technology evolves, newer methods are invented and devices become more sophisticated. The ultrasonic cleaner is one such fine example. There are various methods of cleaning different stuff. However, the precision and accuracy that you get with ultrasonic cleaners are remarkable. This is one of the reasons that the ultrasonic cleaning process is widely used across different industries and stratospheres for the maintenance of equipment. The ultrasonic cleaners are used to clean almost everything these days including rifles, jewelry, engine components, surgical parts, motherboards and even the delicate lenses. The range of items which are cleaned using the ultrasonic cleaning process is huge and that implies the efficiency of the process.

The procedure for ultrasonic cleaning

- You should prepare the cleaning solution as per the manufacturer’s dilution parameters. The quantity of the solution should be according to the capacity of the cleaning tank of an ultrasonic cleaner.

- After you have prepared the solution you must activate ultrasound to mix the solution.

- Once the solution is mixed you can turn off the unit until you are ready for the cleaning process. Disassemble the parts of the equipment as per the manufacturer’s instructions.

- Now place the disassembled components in the basket and set the thermostat at 65 degree Celsius if possible.

- As soon as the ultrasound begins you must put the basket in the solution and set the timer for approximately 10 minutes. After the cycle has ended, remove the basket from the solution and observe the parts. Now you can wipe, shake and allow the components to dry and then lubricate it for smooth functioning.

It is important to note that this procedure differs based on the equipment you want to clean. It is always advisable to read the manufacturer’s instructions before proceeding with the cleaning process. It is also important to understand that ultrasonic cleaning does have its limitations as it cannot work with a few select types of equipment such as accelerometers, gyroscopes, and the microphones. This equipment might get damaged by the high-intensity vibrations that are caused by the ultrasonic cleaning.

Functioning of the ultrasonic cleaners

The main idea behind the functioning of the ultrasonic cleaners is the quick building and the immediate collapse of the microscopic bubbles in the detergent solution. This agitation in the water causes multiple small implosions which in turn produces efficient scrubbing of the visible as well as concealed component surfaces. As the frequency becomes higher the count of those bubbles increases whereas the energy which is expelled by collapse decreases resulting in frequencies in the range of 35 to 45 KHz. This frequency is perfect for the removal of the small particles without causing damage to the surface or the components.

The main idea behind the functioning of the ultrasonic cleaners is the quick building and the immediate collapse of the microscopic bubbles in the detergent solution. This agitation in the water causes multiple small implosions which in turn produces efficient scrubbing of the visible as well as concealed component surfaces. As the frequency becomes higher the count of those bubbles increases whereas the energy which is expelled by collapse decreases resulting in frequencies in the range of 35 to 45 KHz. This frequency is perfect for the removal of the small particles without causing damage to the surface or the components.

Ultrasonic cleaning can be used for removing almost any type of dirt, sludge, oily chemicals such as grease and other stubborn stuff. The remarkable feature of the ultrasonic cleaning is the fact that it does the cleaning without damaging the fundamental components of the machine. As a result, the ultrasonic cleaning is used in a wide range of industries. If you would like one best ultrasonic cleaner to serve your specific needs, we compose the top list of ultrasonic jewelry cleaner, ultrasonic gun cleaners, ultrasonic parts cleaners. These reviews and buying guide will help you find the best model.

Need price for rcbs ultrasonic case cleaner

I am sorry to inform you that this product is no longer available. I will update this article in the near future and thank you for bringing this to my attention. If you check out my article on Top 10 Ultrasonic Cleaners in 2020 Under 35 ounces (1 liter), you may be able to find a cleaner that suits your needs. I am currently checking out the next size up ultrasonic and they should be on the website in the near future.